|

Plasma Technology Limited PTL has developed Electrolytic Plasma Polishing EPP technique to polish different material surface. Unlike the electrochemical polishing, EPP process takes place in solution of inorganic salts and is an ecologically safe polishing technique. PTL can provide turnkey service for the technique.

In EPP process, the metallic workpieces will be anodically polarized and are placed in an electrolytic bath. The electrolyte consists of a solution of about 97% water and 2-4% salt. The process produces gas which completely surrounds the workpiece to be polished and results in establishment of plasma layer. This plasma combined with the electrochemical reactions on the workpiece surface led to a reduction of the roughness as well as removes organic and inorganic contaminants with minimal mass loss. Depending on the material specifications the typical material removal lies between 1-5 um per minute. The geometric shape of the component is almost maintained and very low surface roughness (Ra<0.02um ) and high gloss level can be achieved after the process.

EPP50A Specifications

|

Item No. |

Name |

Descriptions |

|

1 |

Machine Dimension |

L678 x W505 x H906 mm Bench Top Model |

|

2 |

Machine Shell |

SS304 steel |

|

3 |

Tank Size |

L200 x W180 x H100 mm |

|

4 |

Tank Material |

SS316 steel |

|

5 |

Sink Volume |

30L |

|

6 |

Salt Amount |

About 1.5kg per tank |

|

7 |

Machine Door |

Stepper motor driven glass door via linear guide rails to open and close |

|

8 |

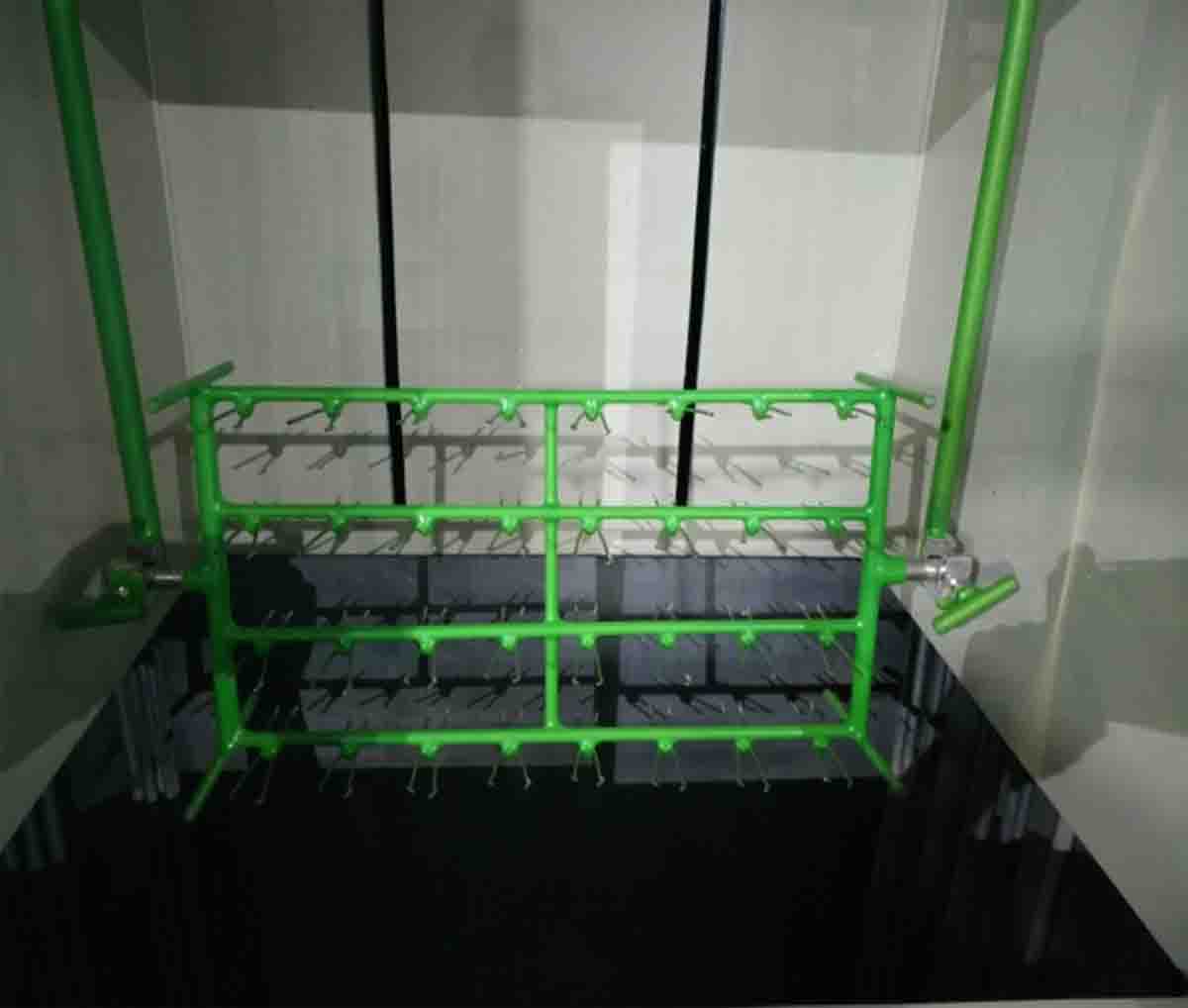

Hanging Device |

Stepper motor driven robotic arm via linear guide rails for lifting and lowering |

|

9 |

Robot Arm Stroke |

220mm |

|

10 |

Water Supply and Water Level Control |

Auto water supply and level control by solenoid valves |

|

11 |

Heating System |

PID control for heating bars. Heating power of 3kW |

|

12 |

HMI Control |

Touch-screen + PLC control |

|

13 |

Power Supply Dimension |

Integrated into the machine rack |

|

14 |

DC Power Supply |

50A with adjustable voltage and current, forced air cooling |

|

15 |

Power Consumption |

15kW |

|

16 |

Input Power |

3-phase 380V, 50/60Hz, 60A |

|

17 |

Protection |

Phase, under-temperature, over-heat and over-current protections |

|

18 |

Footprint |

About 1m x 0.8m |

========================================================

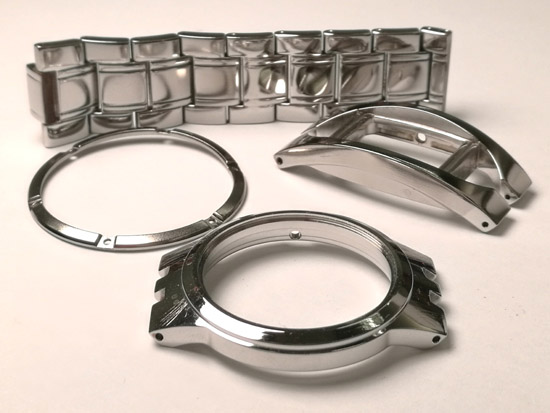

EPP treatment for Stainless Steel SS Watch Components

======================================================== ========================================================

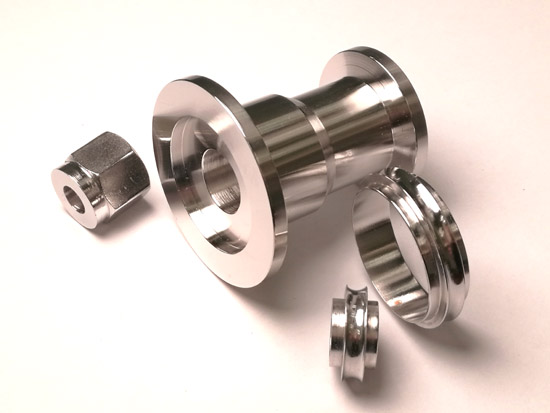

EPP treatment for Stainless Steel SS Vacuum Components

======================================================== ========================================================

EPP treatment for Copper, Brass or Bronze Components

======================================================== ========================================================

EPP treatment for Brass, Copper/Nickel Alloy Coins

======================================================== ========================================================

EPP treatment for Titanium Ti, Titanium Alloy Ti6Al4V and Nickel Titanium Alloy NiTi

|