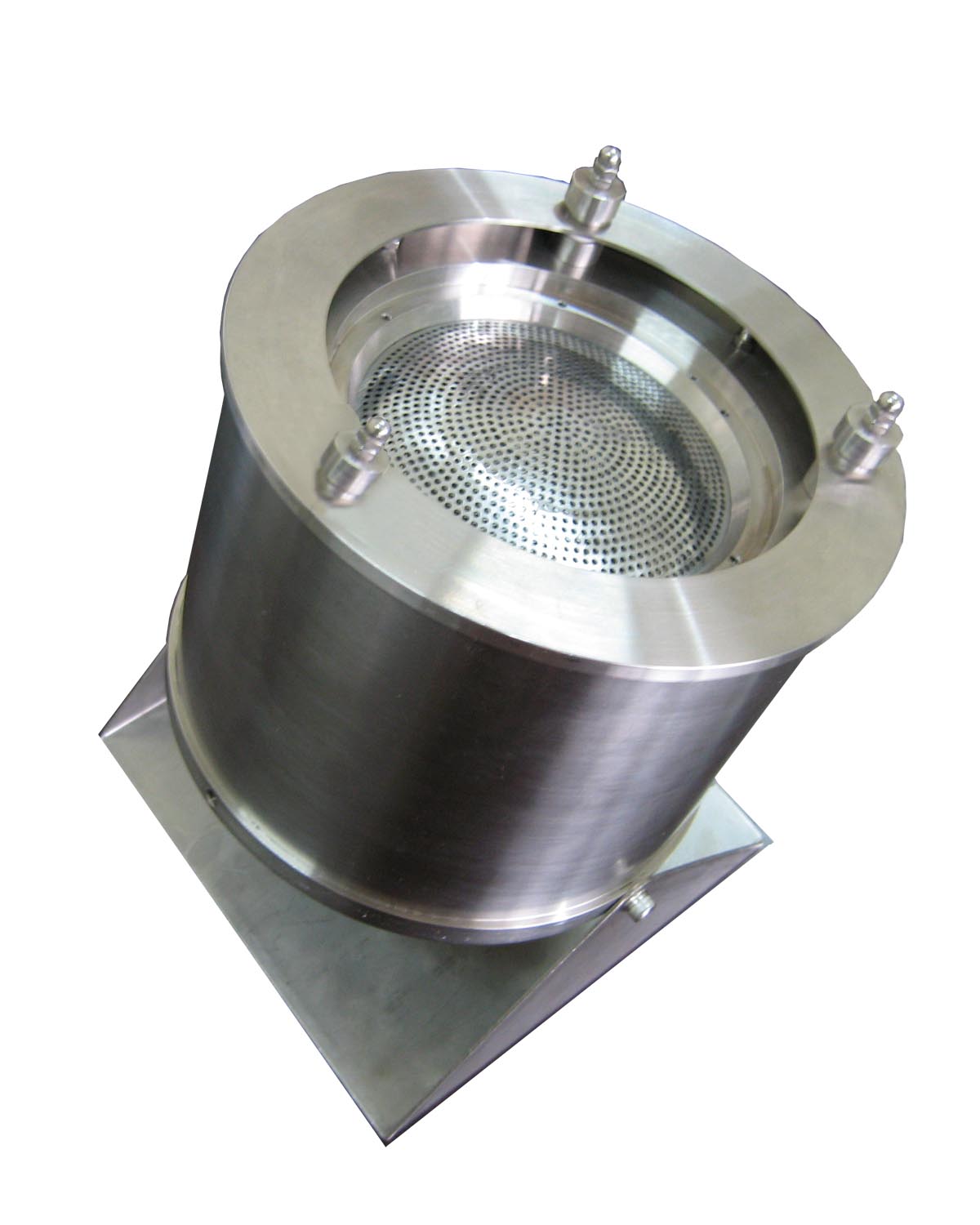

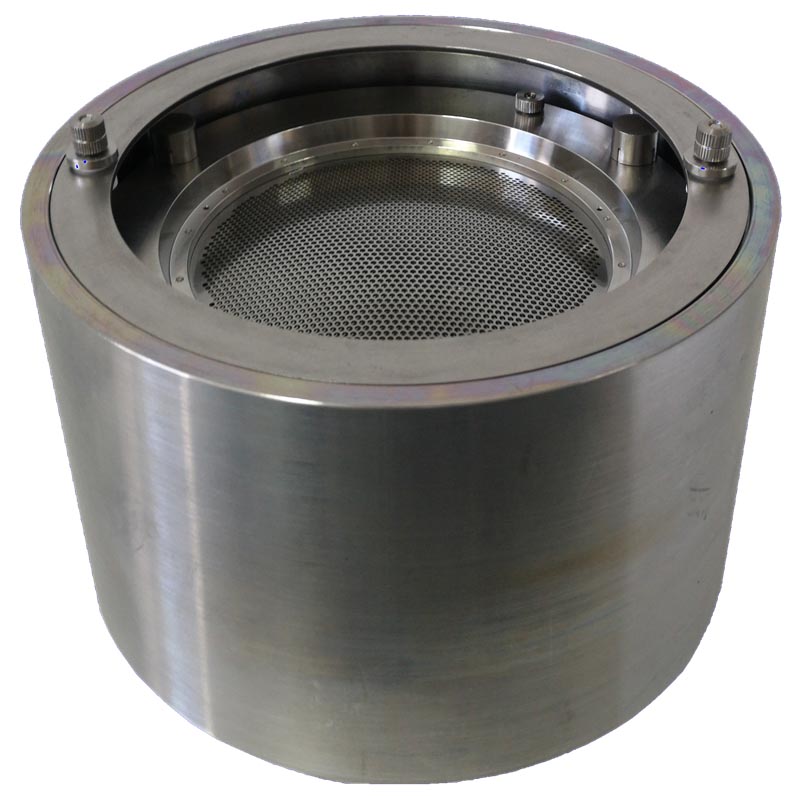

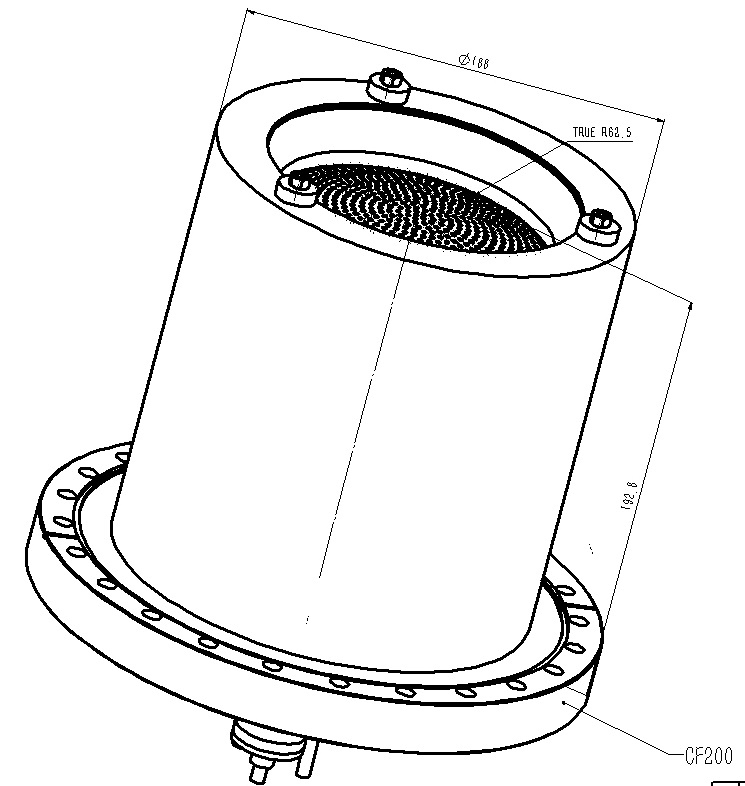

Kaufman Ion Source / Ion Etching / Ion Sputtering

Working Principle:

The ion source is composed of an independent discharge chamber and a double-grid ion extraction system. During operation, the gas is introduced into the discharge chamber and ionized to form a plasma. The ions enter the double-grid acceleration zone through the sheath and converge into an ion beam to be extracted. In auxiliary mode ion source, the energetic ions continuously act on the surface of the substrate or the film to achieve the effect of cleaning the surface and improving the structure of the film.

In etching mode ion source, focused ion beam is obtained through special ion source discharge chamber design. The ion beam current of 20mA/cm2 can be obtained in a small beam spot (<5cm), thereby improving the sputtering rate and target utilization rate of the target, and reducing the contamination of the deposited film by the impurity atoms.

Our Kaufman Ion Source products include broad-beam Gridded Ion Sources and automated power supplies controllers. All designs are straightforward which easily retrofit into existing vacuum systems, or easily integrate into new OEM systems.

Applications:

Ion Beam Assisted Deposition

In-situ Substrate Precleaning

Ion Beam Figuring

Ion Beam Etching

Surface Modification

Ion Beam Sputter Deposition

The versatile gridded series of broad beam ion sources are available in different sizes which covers both R&D and high yield production requirements. Large ion beam sources meet critical output performance for uniform coverage over wide process zones. The large ion energy range permits low energy operation to minimize bombardment damage and heat on sensitive substrates while high energy operation enables high rate sputtering processes

Features:

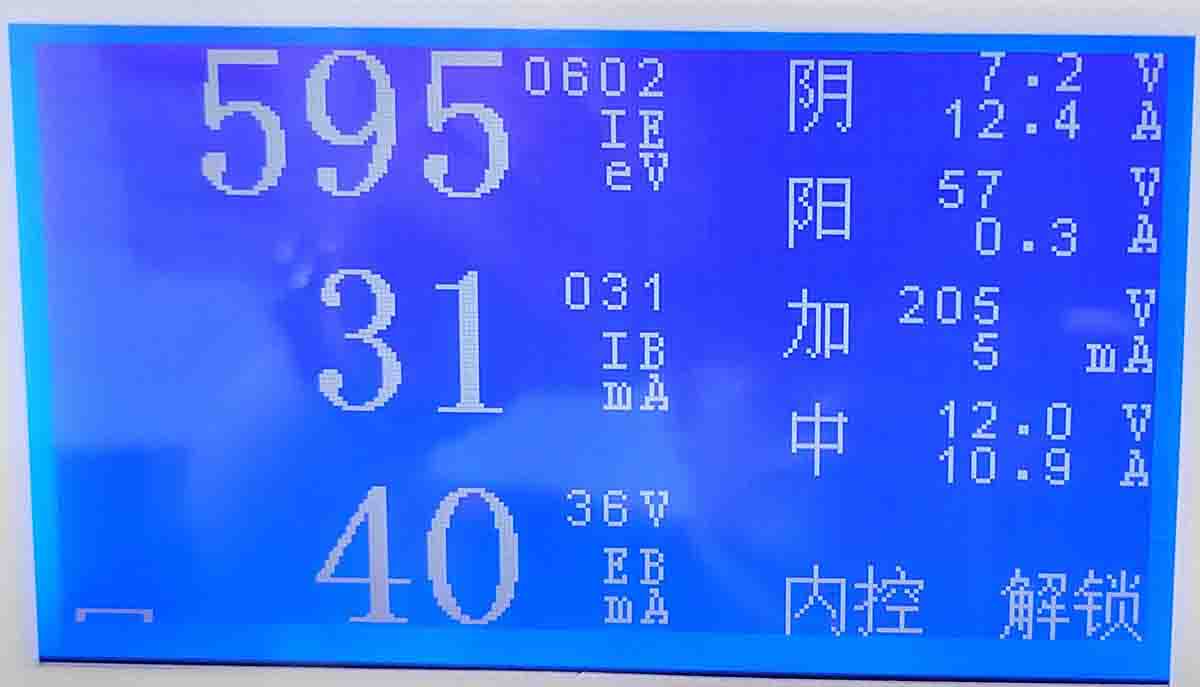

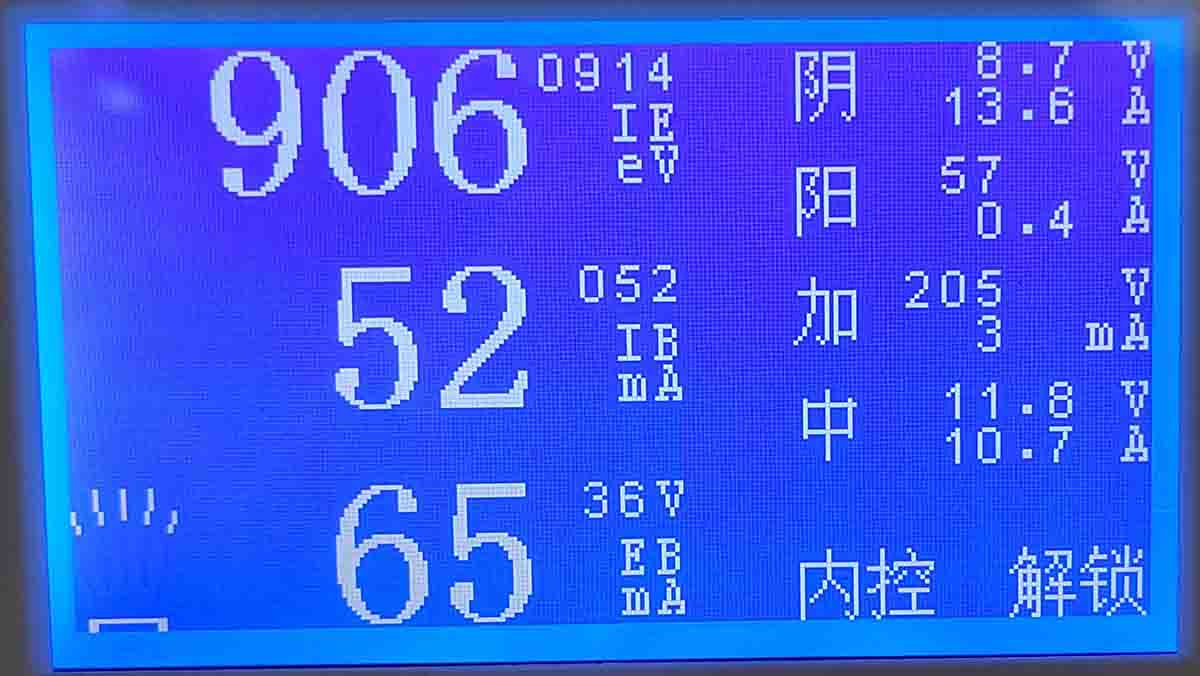

1. High ion energy: up to 600eV, 1200eV, 2000eV or higher;

2. High working vacuum: it can work within 10e-3Pa to ensure the quality of the film layer;

3. Significant effect: it has a significant effect on improving the compactness, firmness and refractive index of the film layer;

4. Easy to use: The new structure solves the troublesome problem of disassembly, maintenance and installation of the original grid and anode;

5. High cost performance: Compared with the RF ion source, the source price, operation and maintenance cost are very low.

> >

For additional product information and pricing contact our specialists at sales@plasmatechnol.com.

|